As a professional manufacturer of outdoor lighting factory, Eurborn has its own complete set of testing laboratories. We hardly rely on outsourced third parties because we already have a series of the most advanced and complete professional equipment, and all equipment is regularly inspected and maintained. Ensure that all equipment can work normally and make timely adjustment and control of product-related tests in the very first time.

Eurborn workshop has many professional machines and experimental devices such as air-heated ovens, vacuum deaeration machines, UV ultraviolet test chambers, laser marking machines, constant temperature and humidity test chambers, salt spray test machines, fast LED spectrum analysis systems, Luminous intensity distribution test system (IES test), UV curing oven and electronic constant temperature drying oven, etc. We can achieve a comprehensive quality control system for every product we produce.

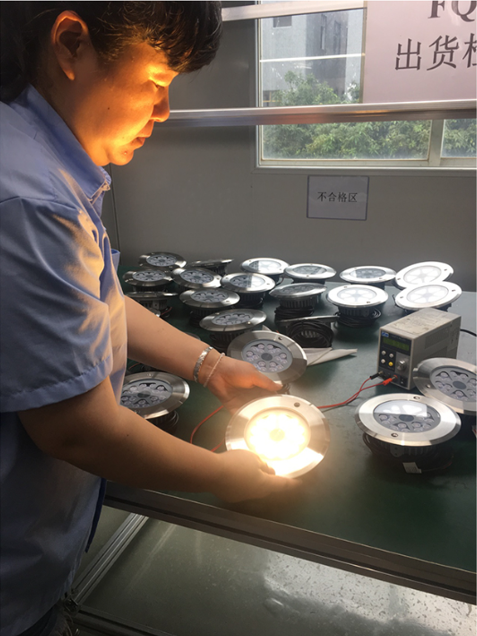

Each product will undergo 100% electronic parameter test, 100% aging test and 100% waterproof test. According to many years of product experience, the environment faced by the product is hundreds of times harsher than indoor lights for outdoor in-ground and underwater stainless steel lamps. We are well aware that a lamp may not see any problems in a short period of time in ordinary environments. For Eurborn’s products, we are more particular about ensuring that the lamp can achieve long-term stable working performance in various harsh environments. In a normal environment, our simulated environment test is several times harsher. This harsh environment can show the quality of LED lights to ensure that there are no defective products. Only after screening through layers will Eurborn deliver the best products to our customer’s hand.

Post time: Nov-02-2022